Latest Innovation from Rollomatic - Sharpening of Diamond Coated Carbide Tools

Diamond coated carbide cutting tools are a great option when machining highly abrasive materials, as the coating properties help to significantly increase tool life relative to uncoated carbide tools. The drawback of diamond coating is the fact that thick-film coating makes the cutting edge dull and thin-film coatings often wear prematurely.

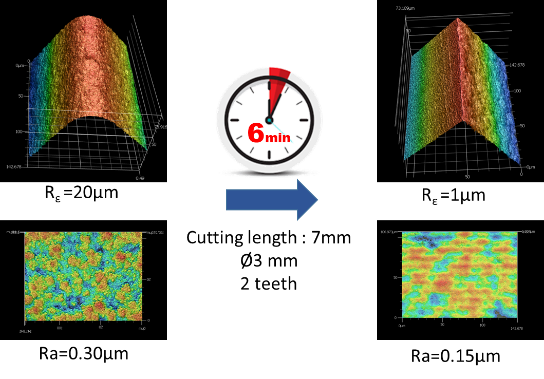

Rollomatic has developed a process that allows sharpening of thick-film diamond coated cutting tools. The Rollomatic CNC Laser Cutting Machine LaserSmart incorporates technologies that facilitate measuring the surface of the coated cutting edge to detect the exact shape and position. Then the laser cutting process will remove just enough diamond coating to make the cutting edge sharp. Only a predetermined amount of the coating, just around the cutting edge, is removed by the laser process.

In-field tests have demonstrated that the tool life can increase significantly with a sharpened thick-film coated tool compared to a conventional diamond coated cutting tool. Such cutting tools are a cost-effective alternative to the far more expensive PCD tools.

For more information on this technology please contact your Rollomatic Sales Manager or Sven Peter, Laser Product Manager, This email address is being protected from spambots. You need JavaScript enabled to view it.

Cutting edge sectional view

Cutting edge radius before and after laser machining of SmartSharpening on LaserSmart 510