VirtualGrind®Pro

VirtualGrind®Pro is the innovative and powerful programming software that comes with Rollomatic GrindSmart® 5- and 6-axis CNC grinding machines.

Designed by our own team of engineers to meet all the requirements of our customers, this software is the result of 30 years’ experience in precision cutting tool grinding.

VirtualGrind®Pro is intuitive, modern, user-friendly and flexible. A perfect combination with Rollomatic precision grinding machines, the user can program and grind all types of high-performance standard or special cutting tools.

Advantages

- All Rollomatic grinding machines come with the complete VirtualGrind®Pro tool package. No additional software options need to be purchased at a later date.

- Rollomatic customers benefit from free software updates throughout the machine’s lifespan.

- The VirtualGrind®Pro has all the necessary functionalities to set up autonomous production.

- A unified interface for the whole Rollomatic ecosystem facilitates the learning curve and communication between the tool designer, production engineer and machine operator.

- Unparalleled programming flexibility with all accessible parameters.

- Machines and software are created and maintained by Rollomatic for unparalleled efficiency.

Tools

The standard package delivered with GrindSmart® series machines includes the following tools:

Drill

Implant drills, form drills, step drills and more

Endmills

Ballnose, spade drills and others

Form tools

With dxf import or by editing the tool shape with the integrated 2D editor.

Burs

Dental and industrial burs and burs for aluminum cutting.

Taps

Inserts

Boring bars

Blank preparation

Key features

VirtualGrind®GPro offers many features that are enhanced after each update.

Tool Sketcher

« Tool Sketcher » software helps you create 2D drawings quickly and easily from 3D tool simulations directly from VirtualGrind®GPro. The drawing can be exported in DXF format or as a PNG image.

Function editor

In VirtualGrind®Pro, all paths and operations are represented by editable functions, providing maximum flexibility in tool programming.

Job manager

With the Job Manager feature, included as standard in VirtualGrind®Pro software, the user can produce series of tools with different geometries from a blank with the same diameter for unattended production.

Models

VirtualGrind®Pro provides more than 70 examples of different tool programs, making it easy to create new tools.

Measurement during the process

VirtualGrind®Pro integrates automatic compensation functionality by making measurements during the machining process, which is convenient for unattended production.

Stick-Smart

The automatic Stick-Smart system cleans the grinding wheel and therefore guarantees constant cutting power throughout production.

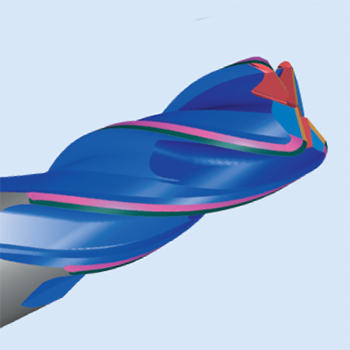

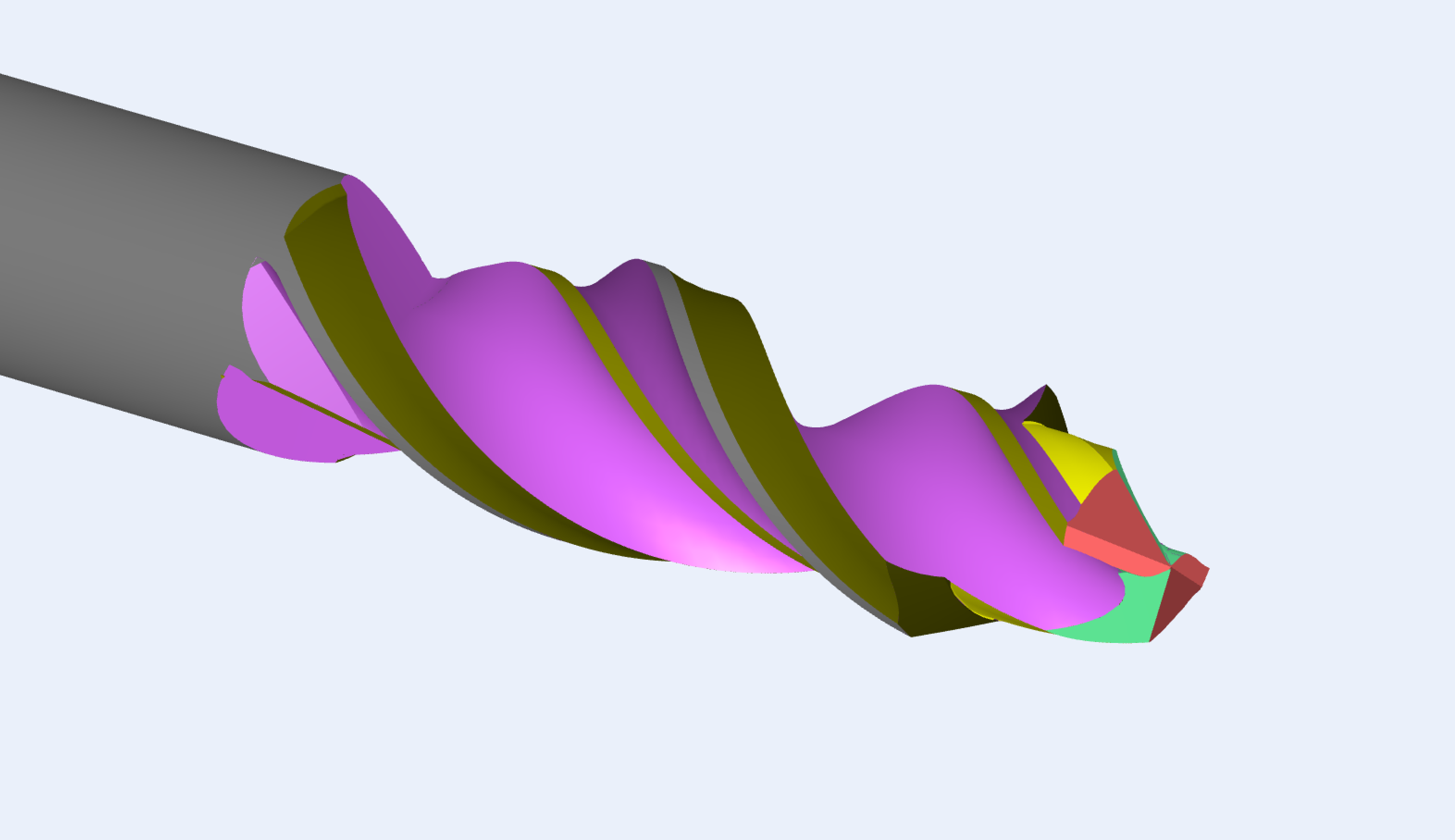

NEW 3D SIMULATION - Version 7

New advantages of 3D simulation version 7.0

To meet the different needs of users, the VirtualGrind®Pro 1.29 programming software now integrates the 7.0 license, which offers many advantages.

Increased speed

Tool simulation is up to 3x faster, depending on the type of application.

Tool center of mass calculation

Version 7.0 introduces a new feature to calculate the tool’s center of mass. The value is calculated and displayed so the operator can balance the tool to reduce vibration during high speed machining.

Floating license

Version 7.0 is sold as a key, so can be used on several different workstations.

Optimized rendering quality

Thanks to this new version, the final simulation rendering is improved to offer a better quality simulated tool.