Insider - June 2017

Three operations, one single clamping!

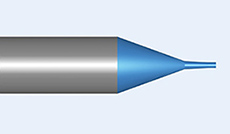

Setup time can have a large impact in terms of productivity especially for small to medium batch production runs. For example, the manufacturing of mold milling tools with long neck, often need to be ground in several steps and on different machines.

The GrindSmart®629XS or GrindSmart®529XF/529XW/629XW allow grinding a complete tool on one single clamping which results in easier production management and setup time savings.

- The first operation consists of reducing the diameter of the front part.

- The second operation then flutes and relief grinds the endmill geometry.

- The last operation involves peel or plunge grinding the tool neck.

This Rollomatic method is particularly adapted to the production of small and mid-sized batches.

THE ADVANTAGES OF GRINDING PROCESS IN ONE SINGLE CLAMPING

- Reduction of setup times ideal for small batches

- Ease of manufacturing process

- Simplified tool production management

Follow us on Instragram!

Today, communication means very often with presence and activities on social media. For the past several months, Rollomatic posts also on Instagram.

Please follow us, like, or share our activities posted our social media to get fresh and instant information about Rollomatic concerning new products and services as well as what Rollomatic employees are up to!

If you want to follow Rollomatic in the US, you can also stay connected with Rollomatic Inc. on Facebook, LinkedIn, & Twitter.

It’s summer now and for some of you that means vacation… Rollomatic wishes you a sunny and relaxing holiday. Be on the look out for the next edition of Rollomatic Insider at September 2017.